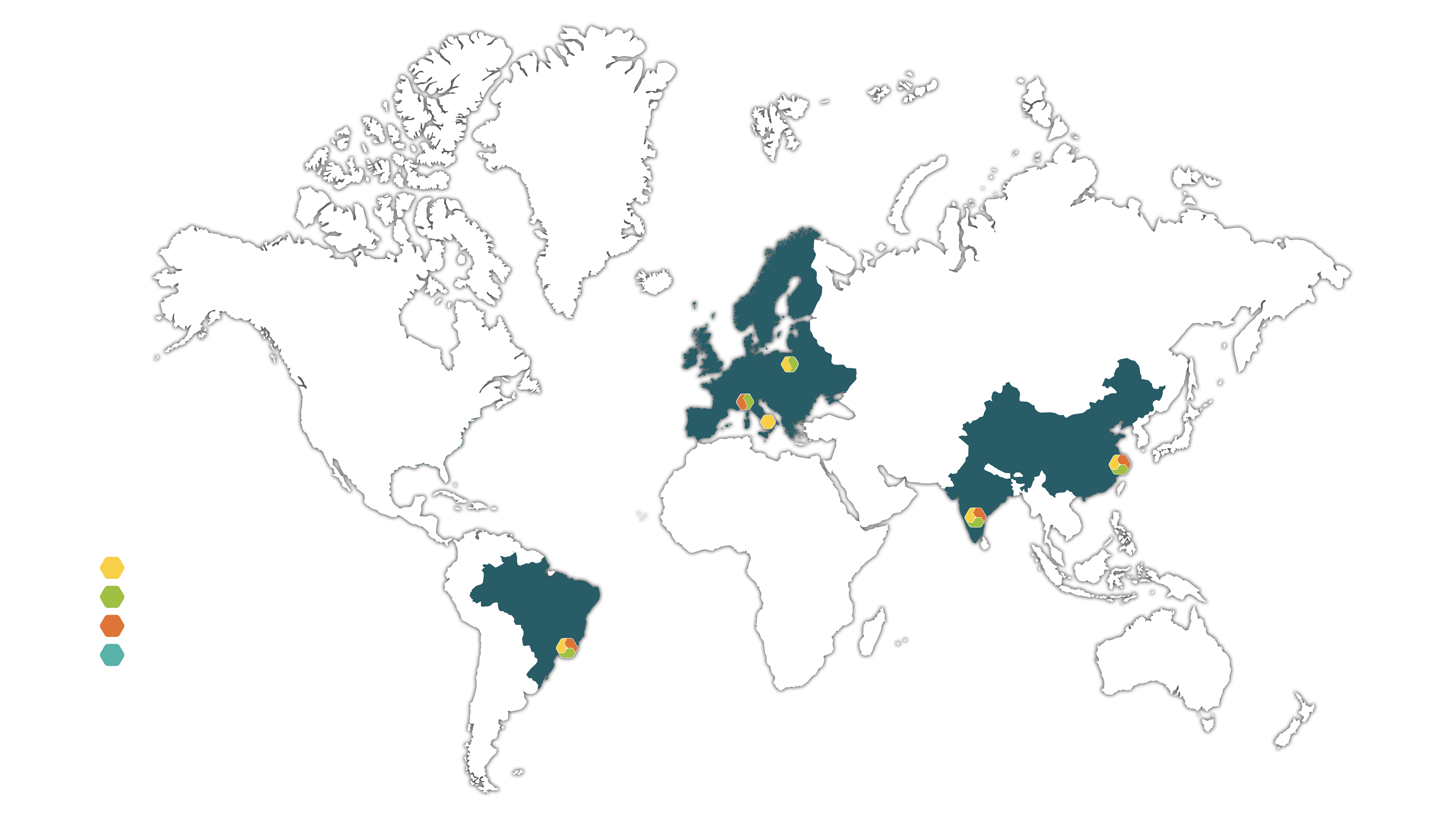

Sila Holding Industriale SpA (originally Società Italiana per la Lavorazione Acciai) was founded in 1943 by Edoardo Brero. Today the Sila group consists of 7 production plants (2 in Italy and 5 abroad) employing more than 1,300 people and is one of the most important global players in the production and distribution of gear shifting systems and flexible remote control cables for major car manufacturers worldwide.

In 1966, Oreste Brero, took over the family company. He promoted a development plan focused on engineering enhancement and the complete customisation of the products according to customer’s specific requirements. In that period, his experience pushed the Company to grow as liable partner, able to support the customer from the very beginning of any programs, thanks to the use of fast and robust prototype technics.

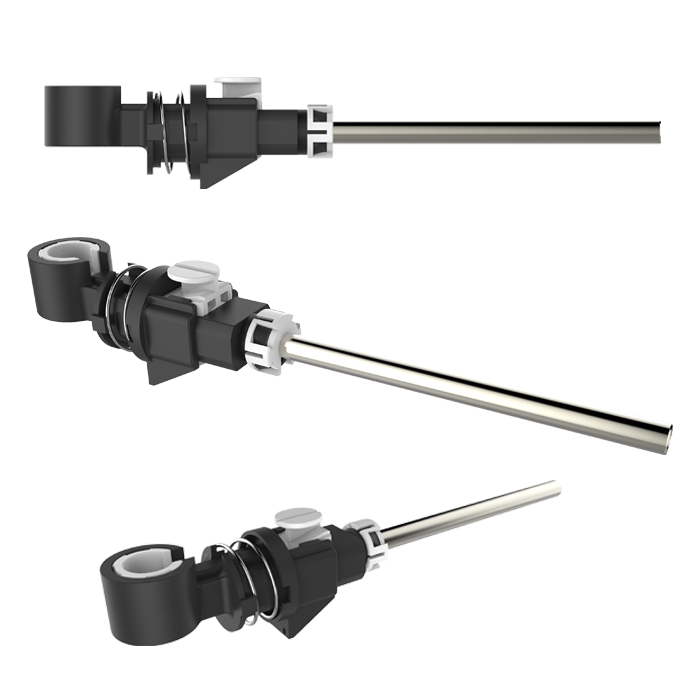

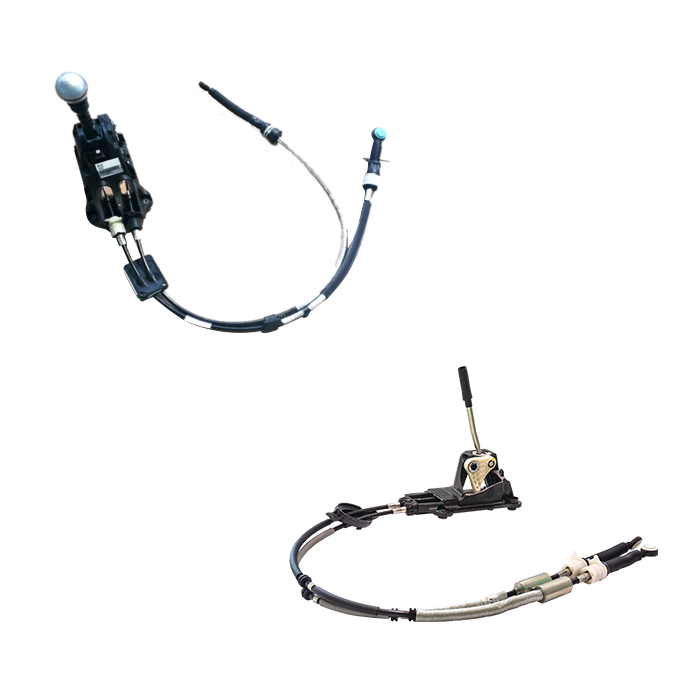

In the Eighties, Sila was the first Company in Europe to develop and produce a complete Gearshifting System based on flexible cables technology (Fiat Uno TD). This system shortly replaced the existing technology (rod linkage) thanks to its capacity to improve the comfort of the vehicle.

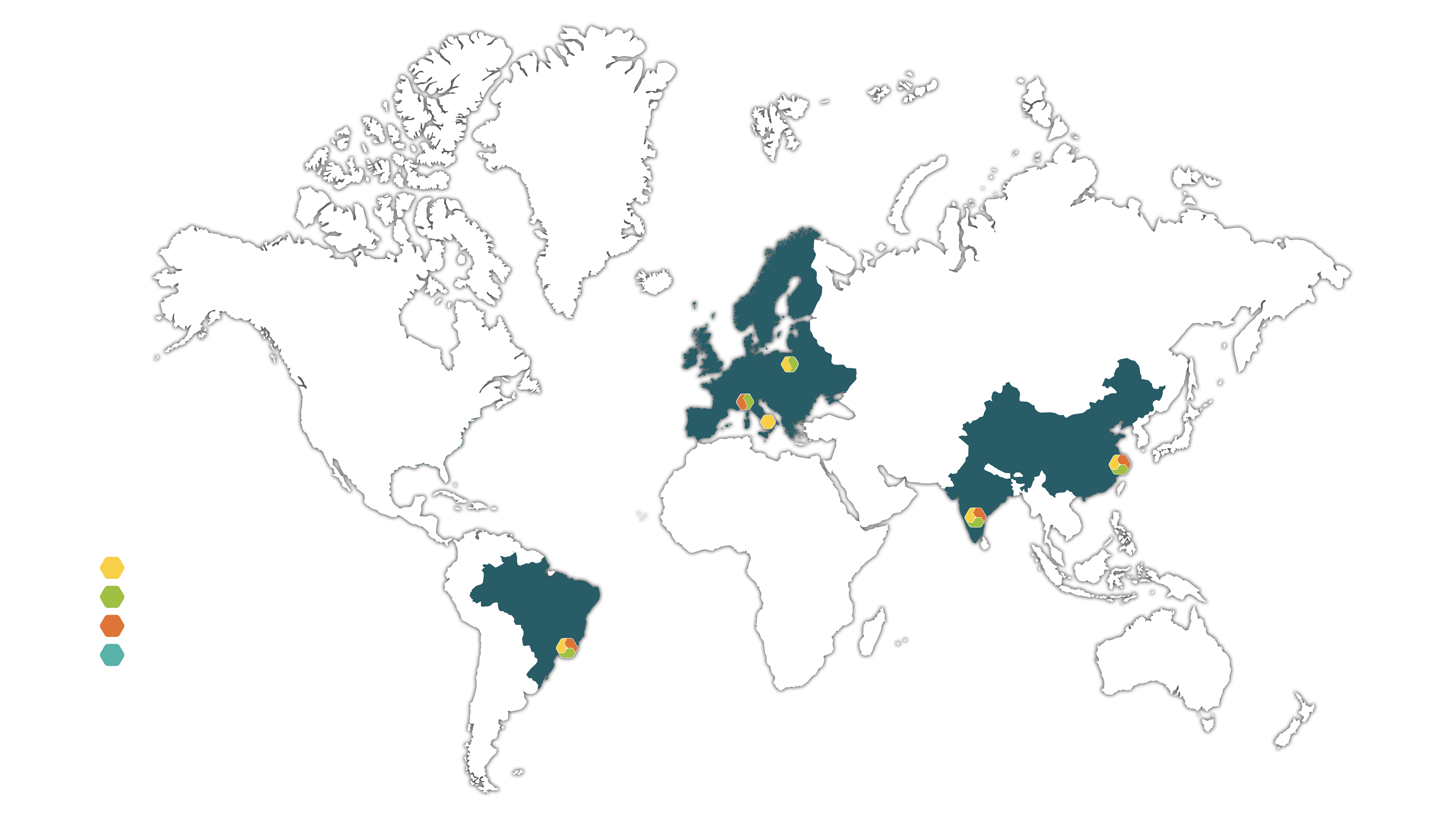

Thanks to the rapid growth as a consequence of the success of its products, SILA increased its production capacity in Italy (new plants in South Italy), in Europe (France and Poland) and, later on, in South America (Argentina, Brazil) and Turkey. All SILA plants, highly verticalized, produce most of the components used in the final product (plastic injection and cable / conduit production).

In 2000, the R&D Center moved into a new Site, in order to host the new advanced NVH and electronic laboratories.

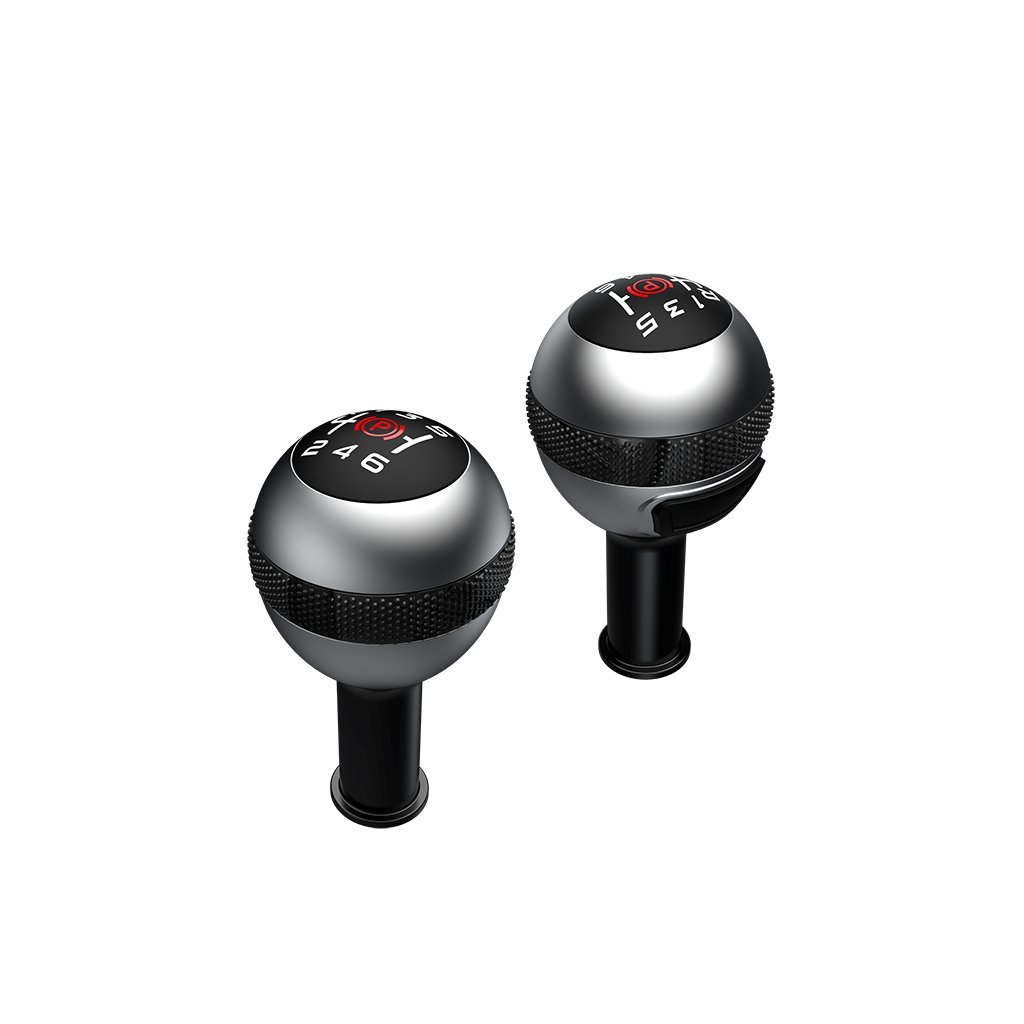

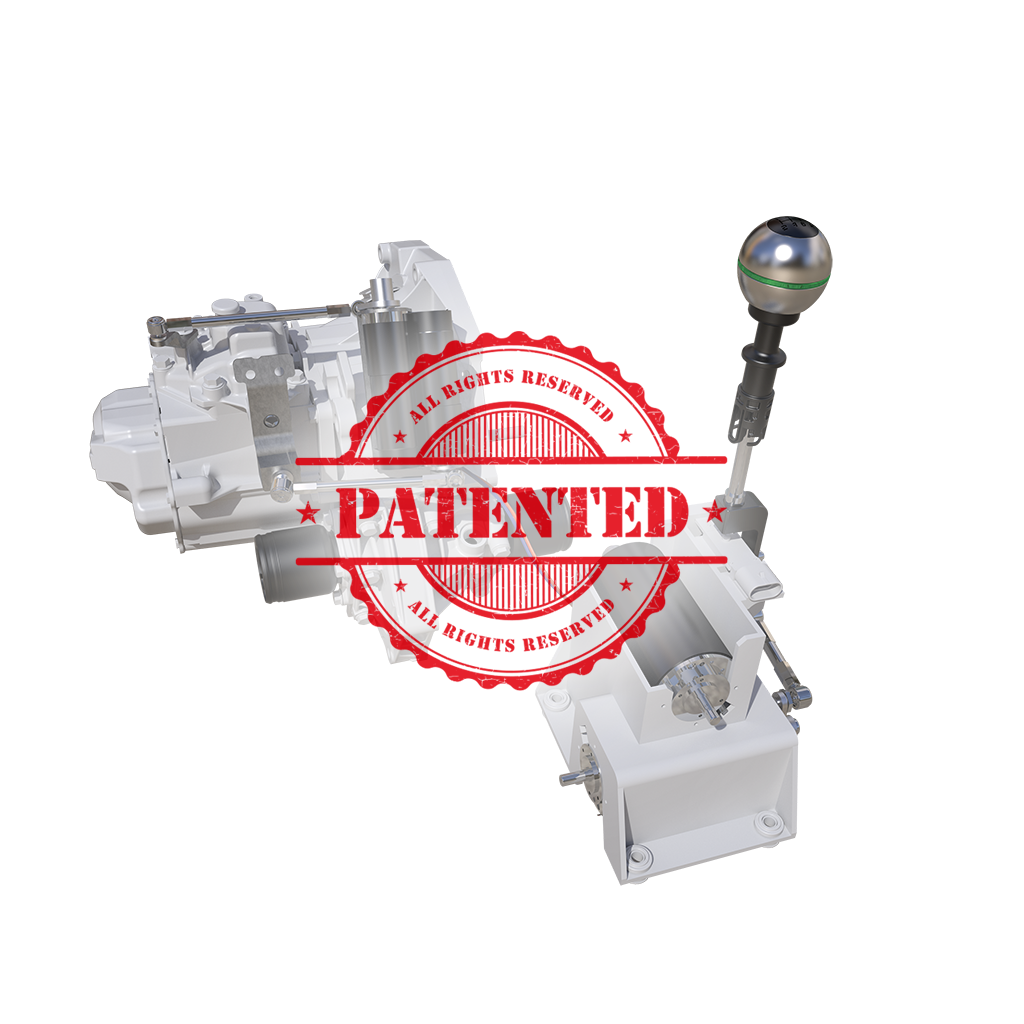

Aside the Manual Transmission Shifter system, SILA applied its experience to Automatic Transmission (1994) and, most recently (2009) to Full-by-Wire Shifting solutions.

Sila has continued developing its customer diversification and globalisation processes by acquiring programs with the major manufacturers in the world. Due to this, Marketing&Sales offices are located, aside where Sila Plants exist, in Germany and Detroit (USA).

Today SILA is proudly a private owned company, led by the successors of the founder. It is working with all OEMs and has active programs with Research Institution (Politecnico di Torino).

Sila estabilished as high pressure hydraulic pipeline producer.

Started production of automotive components of Fiat Group, focusing on gear shifters.

First company in Europe to supply integrated gear shifter systems with "2-cables" technology.

Started international expansion: first foreign plant France.

New plant: Poland.

New plant: Brazil.

New operations in Argentina and Marocco; JV in Turkey.

Consumer diversification started lowering dependence on FCA.

Start of production of the first Shift-by-wire

Silatronic® presented at Berlin Symposium

New operations China & India.

Sold Turkey JV majority share.

Successfully completed Financial Restructuring.

Start Cooperation with IED and Polytechnic of Turin

Start Additive Manufacturing Center in Turin

Advanced Shifter presented at the Geneva Autoshow 2018

VISION

To be recognised as the

Customer's Preferred Automotive Gear Shifter Systems Supplier.

VALUES

Innovation, Collaboration, Co-Design and Co-Program Management

Close to Customers, Globally and Locally

Dynamic, Continuos Improvement, Embrace Change

Teamwork, Respect, Empowerment, Honesty

MISSION

To Grow Market Share by supporting Sila's global customer base with a complete range of Innovative, Leading Technology, Quality, High Performance gear shifter system products, at the right price.

Sila is committed to developing products that meet customers’ expectations and that are launched into the market on time. The best technical solutions are prepared and made available as virtual 3D prototypes. The Finite Element Method (FEM) is used to check critical load conditions under static and fatigue conditions, to optimize component geometries and to run and re-run computer simulation until tension peaks are eliminated. Integrated electronic functions and controls are designed and virtually simulated, using the most up-to-date tools and techniques, complying with the highest standards for hardware and software development (ISO26262, SPICE).

Solutions included in the design to minimize noise and vibrations are verified with specific equipment for acoustic and vibration measurement and analysis. Mechanical and electronic performance, as well as endurance, are tested reproducing real conditions on specific test benches. Actual measurements are continually correlated with the results from virtual validations in order to improve and increase the significance of the simulation models. Interconnected Sila Group technical centres for design and testing are located in Europe, Asia and Latin America, close to major customer development centres. Up to date know-how regarding materials and design techniques is supported by close connection with research centres at universities.

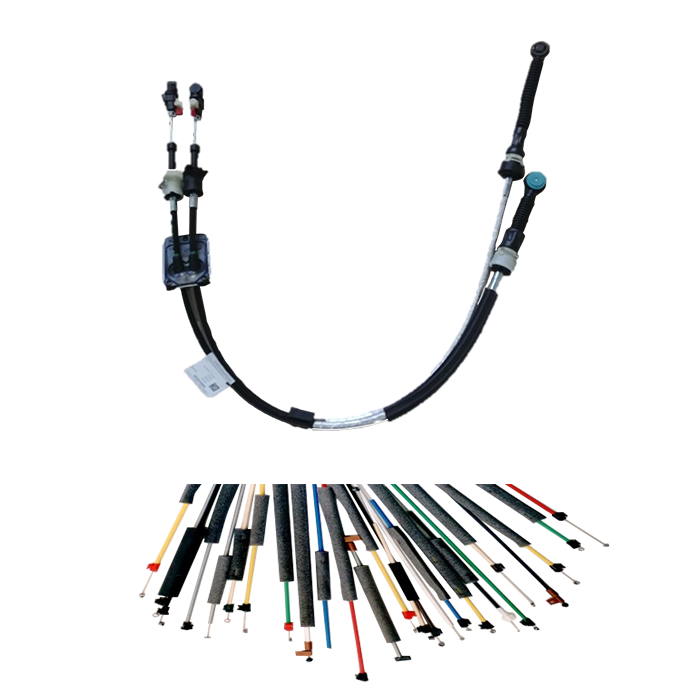

Pull Cables

Push/Pull cables Fiat Uno

AT Shifter & cable Fiat Bravo

Silatronic 1.0

MT Shiftability FCA 500X & Renegade

By wire joysticks Blucar/Gruau

AT shifters high volume gwm

(haval)

Multi function joystick

Silatronic 2.0

Rotary shifter

Park actuator & joystick

Thumb print recognition shifter

Rod to cable replacement

SILA Group is constantly engaged in the improvement of consolidated processes and in the new production processes development, referring to the key principles of Lean Manufacturing.

The goal is to ensure and exceed the performances requested by the Customers and, at the same time, to minimize the activities with low added value. Every day we use fundamental assets such as: teamwork, evaluation of Lesson Learned, sharing of Best Practices and revision of P-FMEA (introducing Error Proofing and Poka Yoke).

The new manufacturing plants are all designed from the perspective of 4.0 Industry, in order to make the production site digitized and interconnected on the outside and inside, starting from Customer orders to the delivery of the finished product.

Crossing all the operational areas, a completely traceable product is generated, both in terms of raw materials used and data historicization of each single production process for each unit of produced product, thus allowing speed, competitiveness and flexibility.

Great attention is placed to workplace safety, environment and to the energetic impact of all new plants: the goal is to constantly reduce energy consumption not only within our companies, but also involving the entire supply chain.

Production processes are constantly monitored with the use of appropriate daily performance indicators: productivity, waste, OEE.

Technologies used in our plants for the realization of the products are:

- Semi-automatic and automatic lines for the finished products assembly, with the aid of robotic systems;

- Plastic molding with injection molding machines;

- Production process of cables and conduit: starting from the laminating of the metal wire to the extrusion of the plasticization for cables and conduit.

- Anti-corrosion electrolytic surface treatment for metals through galvanic processZamac molding for die-casting.

EUROPE / MIDDLE EAST / AFRICA

Registered office and production plant:

Zona Industriale - 66052 Gissi (Ch) Italy

Tel. +39 0873 94321 - Fax +39 0873 9432241

Strada Torino 49 - 10043 Orbassano (Torino)

Tel. +39 011 9001 211 - Fax +39 011 9001 205

Zona Industriale Loc. S. Nicola - 85025 Melfi (Pz)

Tel. +39 0972 76811 - Fax +39 0972 78928

ul.Jana Andrzeja Morsztyna 7/9 42, 200 - Czestochova (Poland)

Tel. +48 343643244 - Fax +48-343643222

ASIA PACIFIC

Khasra No. 970/1,971,NH-8

Delhi-Jaipur Highway

Village Shikohpur Gurgaon

122004 (Haryana), India

No.4 Building-No. 255 Bei He

Road Jiading District, Shanghai - 201807

Tel. +86 21 39968555

Fax +86 21 39968559

AMERICA

Rua Engenheiro Gerhard Ett,

1105 Distrito Industrial Paulo Camilo Sul 32.669-110

Betim (MG) Brasile

Tel. +55 3121913400

Fax +55 3121913401

- With a simple touch, the seat, the mirrors, the temperature and all other settings controlled when getting into the car, can be automatically adjusted according to the driver’s preferences;

- The biometric fingerprint sensor can also be used for menu selection and to adjust for example the radio volume or the GPS in-data;

- The user identification makes it easy to keep track of driving hours, breaks and driving distance, creating a personalized driving journal;

- An audio book or a favorite playlist can be started at the exact moment the driver left it or the backseat passengers can continue their video games at their last achieved level;

- By the use of the biometric sensor, driver’s settings are valid even if someone else has been using the vehicle since he/she last left it.

• Multiple vehicle functions centralized in a joystick

• Much more free space on the vehicle dashboard

• More opportunities to improve interior style

• Haptic feedbacks availability

• High level of customization

• Put one further function on the shifter lever, clearing the tunnel by removing the EPB button

• Allow the insertion/release of the EPB with one “easy to find” command

• Improve driver comfort, through the eRGI, preventing potentially dangerous reverse gear insertion (e.g. prevents insertion of RG while vehicle is moving forward)

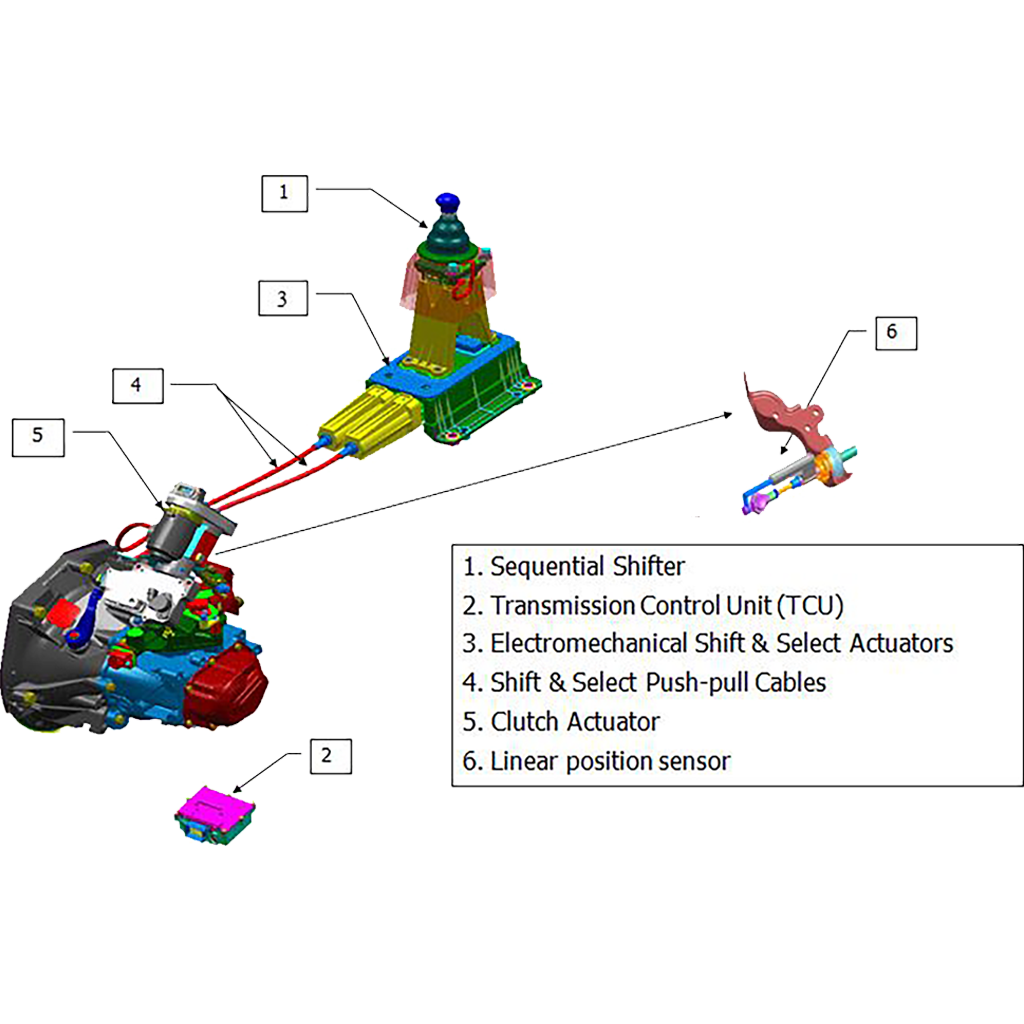

The main benefits given by the EPSystem are:

- No cables needed

- No firewall grommet needed

- No layout constraints

- No vibrations and NVH issues

- No changes on the clutch system

- Perfect shiftability

- Single solution for any gearbox, chassis and/or layout

- Different strokes, loads and feeling available with the same gearbox

- High level of customization

- Console layout not depending on the shifter P point

- More safety on parking mode

Projet MJP 2500: Print the parts with precision printing directly in the office, with realistic print quality and precision, with maximum edge fidelity and surface finish, in plastic and elastomeric materials for a real functional test. Each printer in the series is compatible with robust and versatile hard black and white materials. The ProJet MJP 2500 offers additional material capacity with a rigid, transparent and flexible black elastomer, black and natural elastomer with exceptional elongation and full elastic recovery.

Zortrax M200, Zortrax M300

E-JOYSTICK

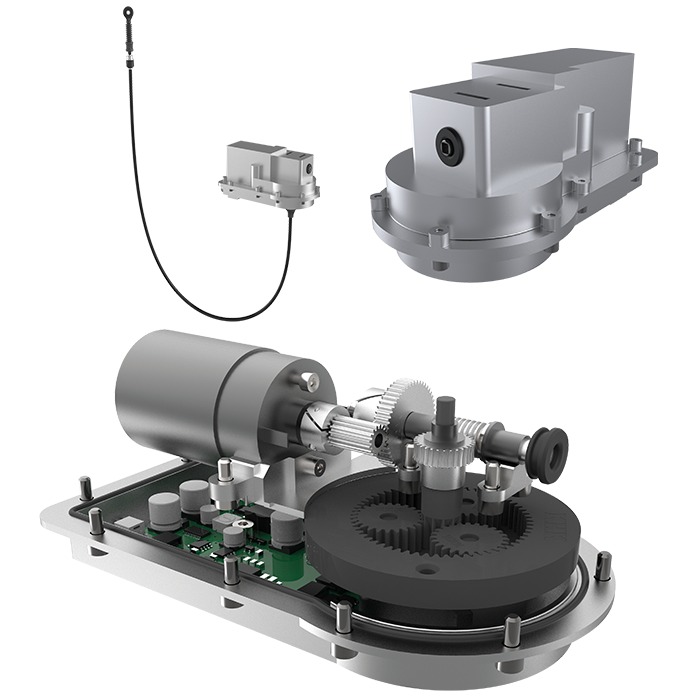

Suitable for any kind of automatic transmission (AT, DCT, CVT, EV, AMT). It is equipped with a patented self-returning system, based on an electromagnetic device. Its reduced packaging and weight make this product one of the top technical solutions for Joystick applications.

E-ROTARY SELECTOR | ROGEM

A flexible solution to control (with a mono-stable or multi-stable configuration) any kind of automatic transmission (AT, DCT, CVT, HEV, EV, MTA)

LINEAR SELECTOR

Suitable for any kind of automatic transmission (AT, DCT, CVT, EV, AMT). Fully designed by Sila, the Linear Selector is the result of a deep design study in order to be ready to face the new market trends. Actually, its led lighting/back-lighting, materials, surface treatments, dimensions and low weight make the Linear Selector a simple and unique PRND solution.

Pull cables for various system control applications (brake, clutch, accelerator).

NEWS

13/06/2023

Interview with the program "Porta a Porta" by Dr. Pavesio.

Our #Silagroup #Silatech President #PavesioEdoardo was interviewed by famous italian newscast talk show #PortaaPorta about future of the automotive and how Silagroup is approaching the new challange for the European Green Deal. #Silagroup #Silatech support all worldwide carmakers on technology transition with their #innovative and #disruptive new patented products and techologies for a new vision of mobility . Stay tuned and follow our pages to be updated about our next steps !

20/04/2023

TUC TECNOLOGY

After the announcement of a new partnership with TUC, a new step has been taken in our new journey, today during a streaming event the new and disruptive technology of TUC was unveiled. Below you will find the link to watch the complete video and attached you can see the frame in which the CEO of TUC presents Silatech as a partner and its SMART device. This is just the first step of the new technologies that Sila is introducing! https://www.youtube.com/watch?v=wG1MQnDA3Gs&t=13s

04/04/2023

TUC Technology

We are proud to annouce and to unveil a new partership between Silatech and Tuc S.r.l. Since many years Silatech is developing new and disruptive technology for automotive and mobility and in the last years it has accelerated the development of components for BEV and Hybrid vehicles in line with the ongoing process of technological change for carbon neutrality, focusing on the customers and markets needs and leveraging its ability to innovate in a flexible and dynamic way . Silatech choosed Tuc srl as technological partner to start a new journey Program with the aim of developing new active haptic devices that talk to the vehicle using TUC.technology solutions . Stay tuned and follow our pages #Silatech #Silagroup to discover next step of our journey and events . https://www.linkedin.com/feed/update/urn:li:share:7047511188309471232/ https://www.linkedin.com/feed/update/urn:li:share:7047536577199153152/ https://www.tuc.technology/ #Silatech #Silagroup #Activehaptic #Shiftbytouch #Tuc.technology

MULTIMEDIA

02/05/2024

Comunicazione ai sensi del D.L. 19 maggio 2020, n. 34, c.d. “Decreto Rilancio” 02-05-2024

Sila Group Job Position

Sorry, there are no available positions

SILATECH S.p.A.

info@grupposila.com

PEC: silatech@legalmail.it

Marketing & Sales

marketing@grupposila.com

Investor Relator

investor@grupposila.com

Supplier

supplier@grupposila.com

Research & Development

research@grupposila.com

EUROPE / MIDDLE EAST / AFRICA

Registered office and production plant:

Zona Industriale

66052 Gissi (Ch) Italy

Tel. +39 0873 94321

Fax +39 0873 9432241

Strada Torino 49

10043 Orbassano (Torino)

Tel. +39 011 9001 211

Fax +39 011 9001 205

Zona Industriale Loc. S. Nicola

85025 Melfi (Pz)

Tel. +39 0972 76811

Fax +39 0972 78928

ul.Jana Andrzeja Morsztyna 7/9 42

200 Czestochova - Poland

Tel. +48 343643244

Fax +48 343643222

ASIA PACIFIC

Khasra No. 970/1,971,NH-8

Delhi-Jaipur Highway

Village Shikohpur Gurgaon

122004 (Haryana), India

No.4 Building-No. 255 Bei He

Road Jiading District, Shangai - 201807

Tel. +86 21 39968555

Fax +86 21 39968559

AMERICA

Rua Engenheiro Gerhard Ett,

1105 Distrito Industrial Paulo Camilo Sul 32.669-110

Betim (MG) Brasile

Tel. +55 3121913400

Fax +55 3121913401